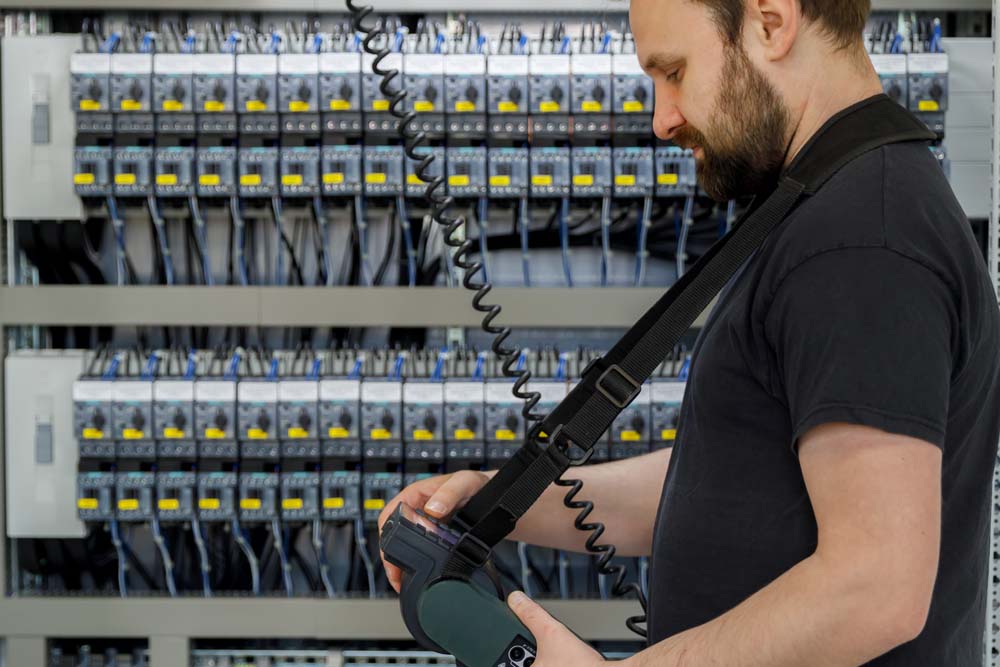

CONSULTING + PLANNING

From individual control cabinets to large industrial plants – we are there for you. A smoothly functioning production with maximum planning reliability and low downtimes is our top priority.

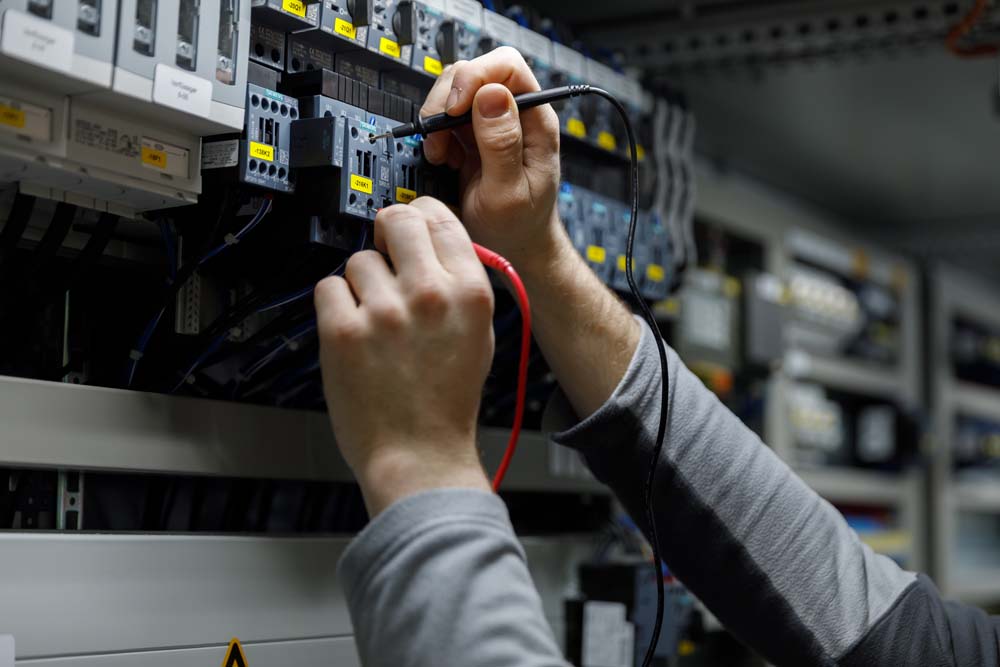

Precise planning with E-Plan 8

That is why we place great importance on precision – right from the planning stage. By the way, we do this with E-Plan P8. The required documents in E-Plan include:

Do you already have a specification? We will be happy to work with it. Or we can draw up a specification together with you.

Interested?

No matter whether you want to build new machines and plants, or expand, convert and modernize existing ones, we will advise you and take over the planning.